MaxBiogas workshop 2023

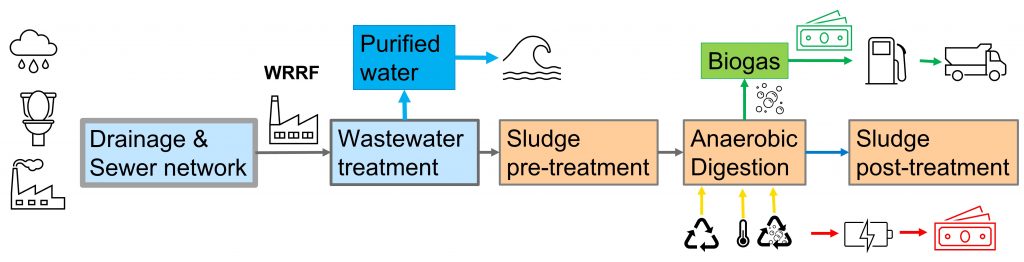

In the beginning of December 2023, our project group and partners from Veas gathered at OsloMet to go through our achievements of this year. Tiina Komulainen summarized the project. Matthew Stanford presented the Demo webapp. the Per Ola Rønning and Bita Joudi presented the fatty acid analysis methods and results for 40 daily samples from Veas WRRF. Truls Ødegaard showed the results of the modeling and control (SIMS2023 article) and initial work on modeling using DHI’s West software. Sheik Tawfique Elahi presented his background and ideas for his master’s thesis were discussed.

MaxBiogas workshop participants. From left: Tiina Komulainen, Bita Joudi, Per Ola Rønning, Morten Rostad Haugen, Hilde Johansen, Truls Ødegaard, Rune Holmstad, Sheik Tawfique Elahi, Matthew Stanford.