Laundry Care Regimes: Do the Practices of Keeping Clothes Clean Have Different Environmental Impacts Based on the Fibre Content?

Kirsi Laitala, Ingun Grimstad Klepp, Roy Kettlewell & Stephen Wiedemann

Abstract

Clothing maintenance is necessary for keeping clothing and textiles functional and socially acceptable, but it has environmental consequences due to the use of energy, water and chemicals. This article discusses whether clothes made of different materials are cleaned in different ways and have different environmental impacts. It fills a knowledge gap needed in environmental assessments that evaluate the impacts based on the function of a garment by giving detailed information on the use phase. The article is based on a quantitative wardrobe survey and qualitative laundry diary data from China, Germany, Japan, the UK and the USA.

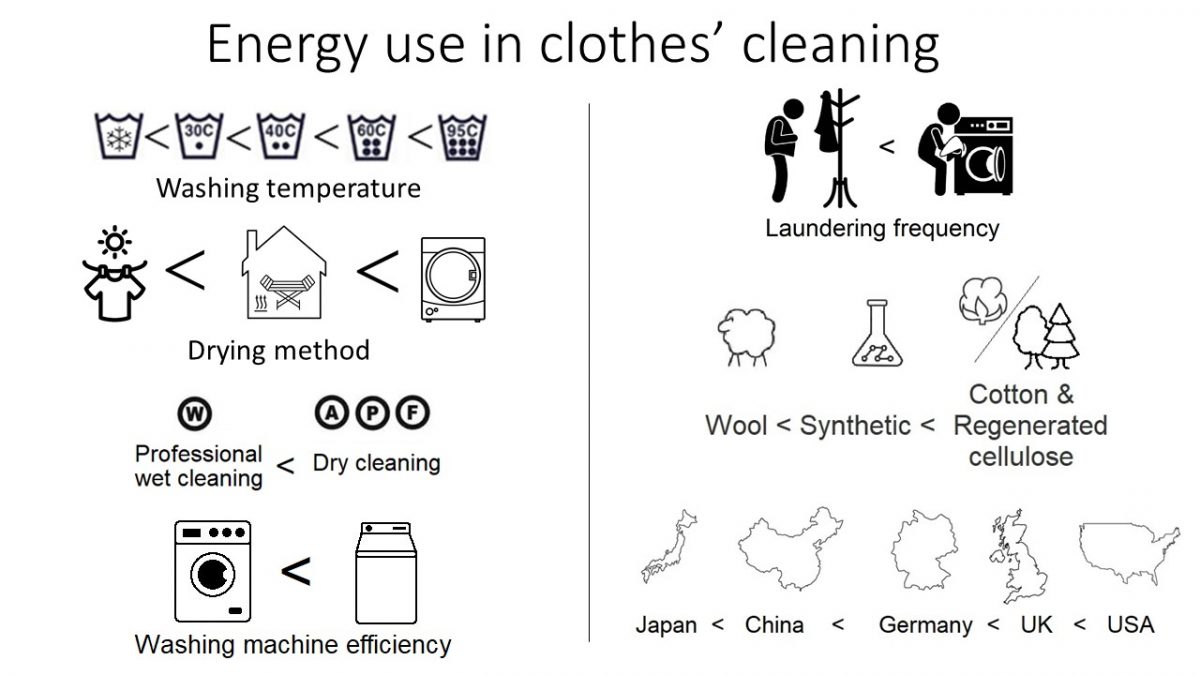

The largest potential for environmental improvement exists in reducing laundering frequency and in the selection of washing and drying processes, and through a transition to fibres that are washed less frequently, such as wool. Adopting best practice garment care would give larger benefits in countries like the US where the consumption values were the highest, mainly due to extensive use of clothes dryers and less efficient washing machines combined with frequent cleaning. These variations should be considered in environmenta assessments of clothing and when forming sustainability policies. The results indicate the benefits of focusing future environmental work on consumer habits and culture and not only technologies.