Siste Woolume-møtet med blikk fremover

Etter at flere av Woolume partnerne hadde vært i Dronning Mauds stall og tatt del i vev-symposiet Samlende tråder 17. april med kronprinsesse Mette-Marit og dronning Sonja som vertskap, bar det av sted til SIFOs lokaler for å oppsummere det aller siste arbeidet i Woolume prosjektet og utøve en siste innspurt med kunnskapsoverføring og en diskusjon om veien videre.

Møtet ble kombinert med at styret i Fibershed Nordenfjeldske ville høste erfaringer fra Woolume, samt at gründer Rosa Pomar var kommet fra Portugal for å få del i samme kunnskapsutveksling – særlig med tanke på fremtidig samarbeid. Under sluttkonferansen til Woolume i Istebna/Koniakow i Polen, hadde våre tidligere partnere i hiWool prosjektet kommet for å bidra med enda mer kunnskapsutveksling i aksen Polen-Portugal-Norge, så det falt derfor naturlig å følge dette opp med den mest kunnskapsrike personen på Portugal og ull: Rosa Pomar. At hun fikk skikkelig innblikk i forholdene for ull i Norge, var en viktig forutsetning for utvekslingen.

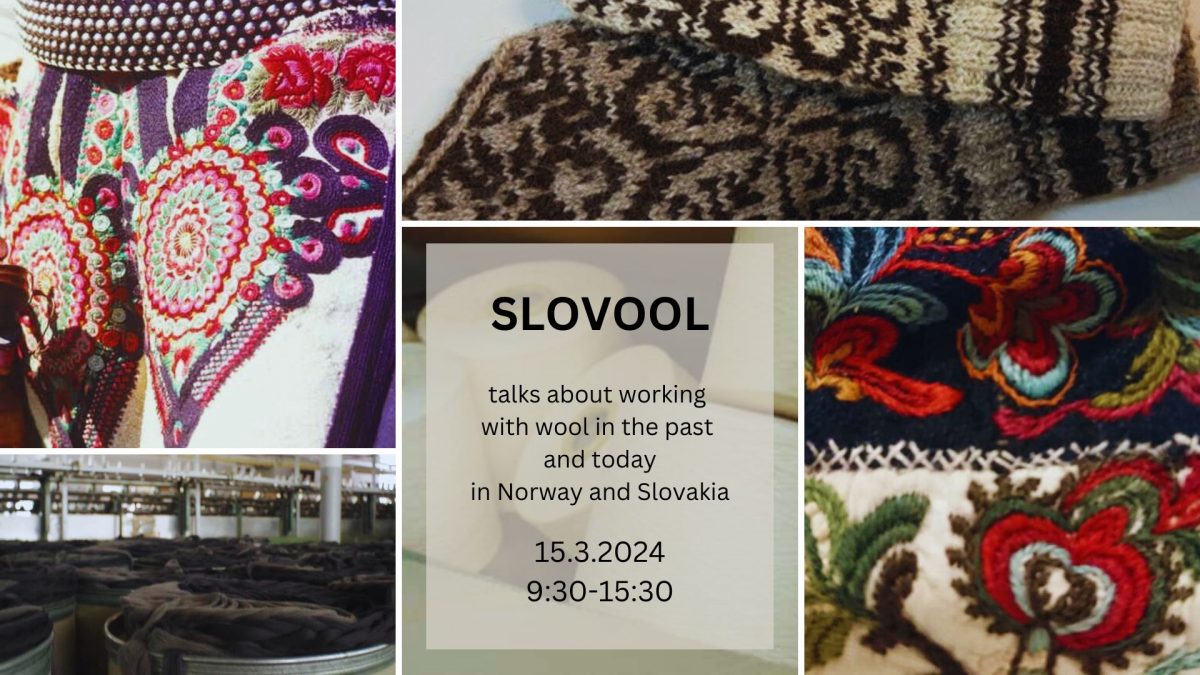

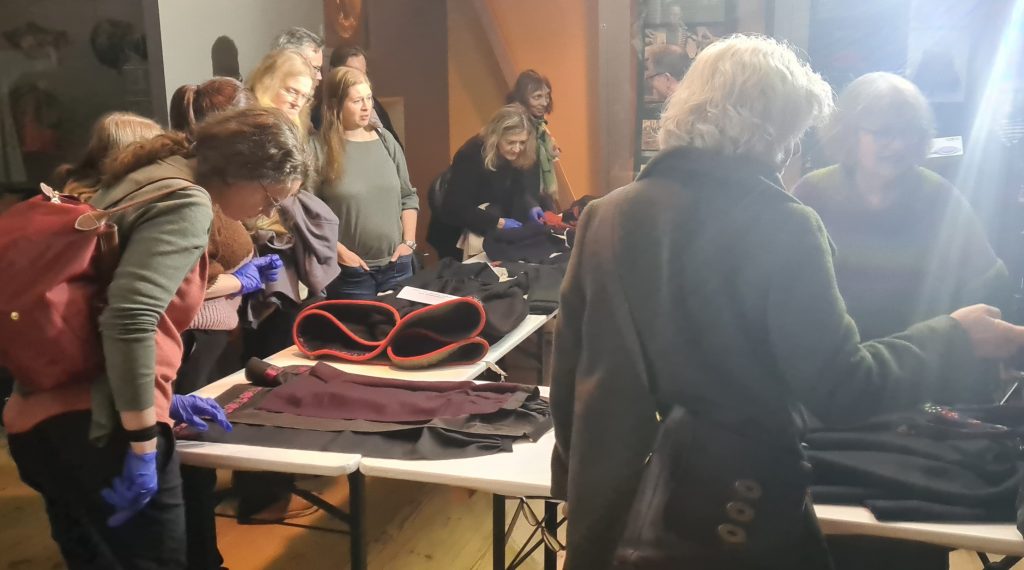

Portugal er nemlig et land med en stor og moderne tekstilindustri, men som i liten grad utnytter lokal ull. Derfor er læringspotensialet stort, for å forstå hva som her har hindret bruken av egen ull. I mellomtiden hadde et annet prosjekt avstedkommet resultat i rekordfart, Slovool, som også var et EEA Norway Grants prosjekt, men denne gangen med Slovakia. Og her var det faktisk sluttkonferansen til Woolume i Istebna/Koniakow som førte til at prosjektet ble søkt om i rekordfart og gjennomført allerede før påske 2024. Her var det også viktig læring, da Slovakia har mange likhetstrekk med Polen som post-Sovjet stat, og også her er den lokale ullen i liten grad utnyttet, tross mye bruk av ull for eksempel i folkedraktene.

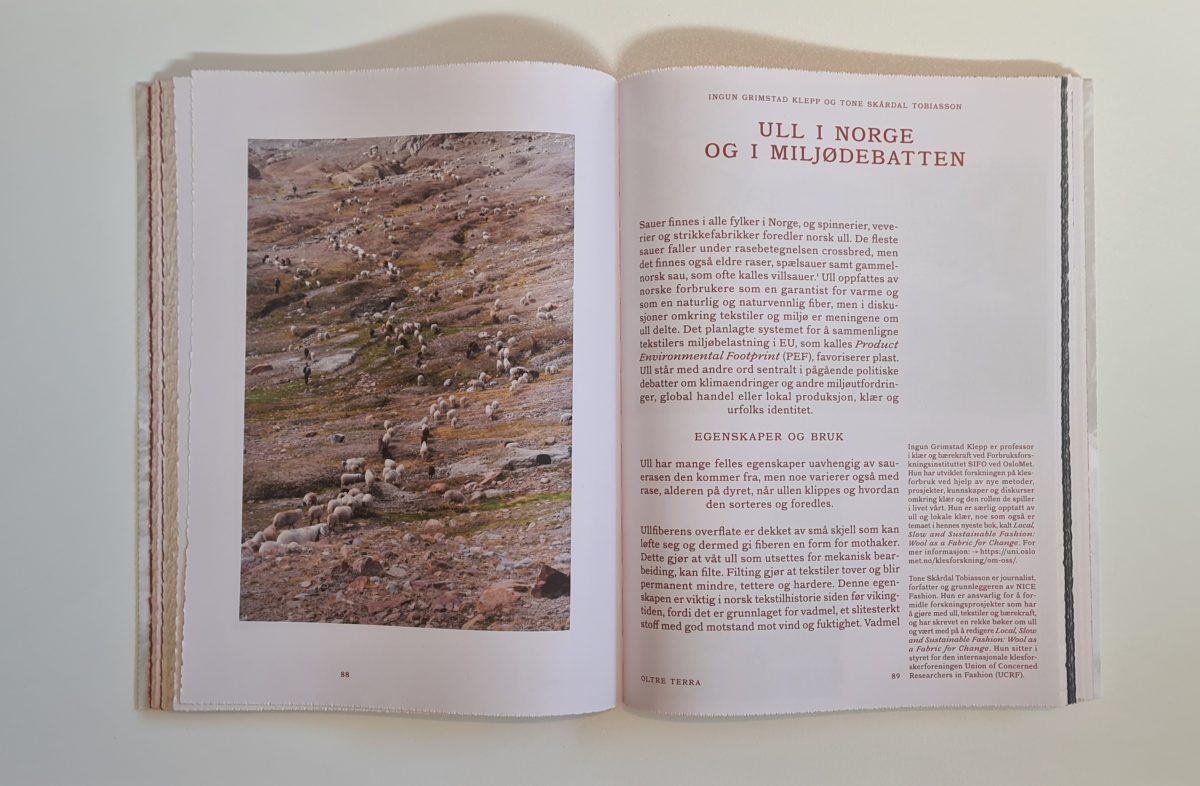

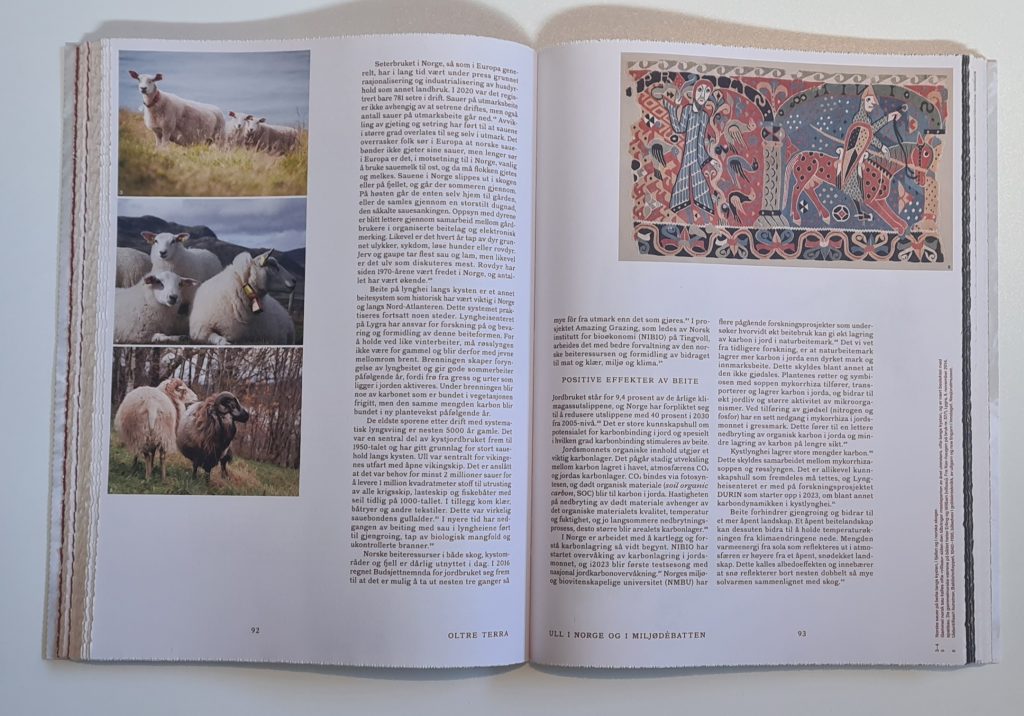

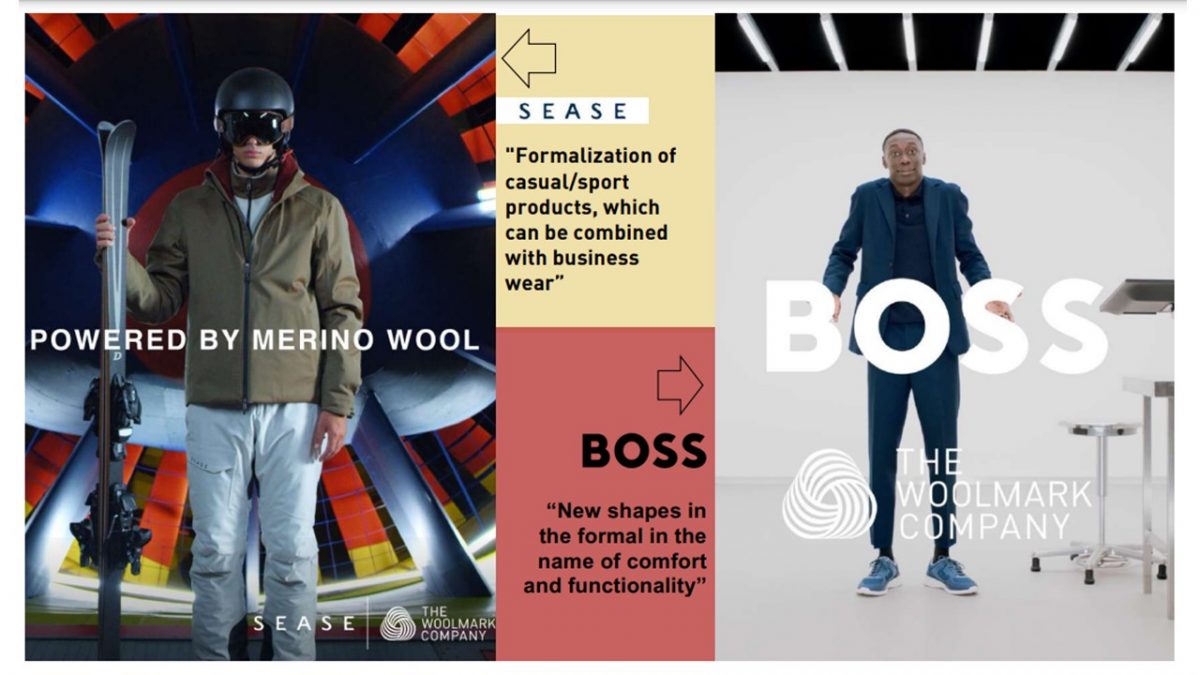

Alt dette ble diskutert i løpet av det som ble en sen kveld, og ikke minst et av de store utfordringene som har kommet til overflaten under Woolume prosjektet, og som videreføres i Amazing Grazing, Wasted Textiles, Change, Fibershed Nordenfjeldskes arbeid med Tekstilbønder og muligens et fremtidig EU-prosjekt: Hvordan ull fremstår som miljøversting i måleverktøy for bærekraft og hvordan dette skader både småbedrifter og hele sauenæringen.

Her har SIFO skrevet mye, i kronikkform, i sammenheng med ullutstillingen Oltra Terra på Nasjonalmuseet, i boken Local, Slow and Sustainable Fashion: Wool as a Fabric for Change, slik at det er mye å hente for å jobbe videre med dette. I tillegg har SIFO nettopp levert til EU-høringer på EUs Product Environmental Footprint Category Rules for Apparel & Footwear, og jobber for øyeblikket med høringsuttalelse til den franske merkeordningen. I tillegg er SIFO i dialog med European Wool Association om en COST søknad, hvor WOOLUME teamet i Polen også er på banen. Dette er et stort nettverksprosjekt mellom akademiske institusjoner først og fremst, men det tangere også Fibersheds arbeid i Europa, så det blir spennende å se hvor veien går videre!