VikingGull: historie og mote vevet sammen

Mote møtte kulturhistorie i prosjektet VikingGull, og sammen ble de vevet til et vakkert ulltekstil, som fant veien til museumsutstillinger og NRK-programmet Symesterskapet som fremtidens mest bærekraftige materiale.

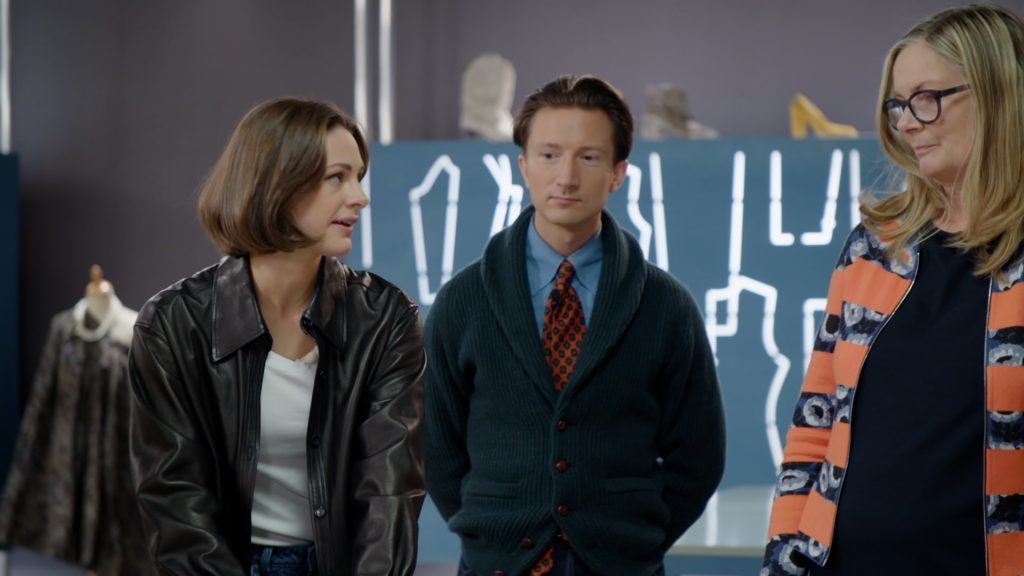

I sammenheng med Oslo Runway høsten 2022, debuterte skuespiller Iselin Shumba på motemoloen som var satt opp i en utemøbelfabrikk langt inni Finnskogen. Helt tilfeldig var jeg der som journalist og helt tilfeldig hadde jeg også på meg Oleana-jakken jeg hadde brukt under innspillingen av Symesterskapet episoden hvor Iselin Shumba var «kunde» som ønsket seg en frakk hun kunne ha på seg på sine ukentlige «sitte foran Stortinget for klima» demonstrasjon, som foregår uansett vær og vind. Hennes ønske var at stoffet i denne frakken skulle være så bærekraftig som mulig, og det var derfor NRK hadde ringt meg. Hva kunne det være? Noe fra en mystisk sopp eller resirkulert et eller annet? At jeg trakk frem akkurat VikingGull stoffet, sjokkerte først men etter en lang samtale så de poenget. At vi i tillegg hadde igjen flere hundre meter med dette stoffet etter at VikingGull prosjektet var avsluttet, og NRK dermed kunne få tilgang på det, var selvsagt også et godt innsalgsargument. De andre soppbaserte eller resirkulerte materialene var det derimot nærmest umulig å oppdrive for en tv-sending.

Poenget var uansett, at da Iselin Shumba så meg i Oleana-jakken, kom hun nærmest løpende bort til meg og fortalte at jakken som hun bruker ofte både foran Stortinget og i andre sammenhenger, har hun fått så mye skryt for. Og særlig hver gang hun forteller historien om bakgrunnen for stoffet, blir folk fascinert.

Vil du vite mer om den historien, kan du lese mer her, på engelsk. Prosjektet VikingGull var et KreaNord prosjekt, og et samarbeid mellom Norwegian Fashion Institute (nå NF&TA), SIFO, Historisk museum og NICE Fashion, og Norge samarbeidet i prosjektet med Island. Fra Norge var Selbu spinneri, Hillesvåg Ullvarefabrikk, Krivi Vev og Sjølingstad viktige aktører for å få på plass «verdens mest bærekraftig» tekstil.